With the European Green Deal setting the ambitious target of reducing greenhouse emissions by 55% by 2030, and with the EU’s proposition to ban sales of all internal combustion engine (ICE) vehicles from 2035, transitioning to electric buses has never been higher in the priorities of public transport fleet operators. Electric bus sales are forecasted to grow by 83% in the next two decades, also thanks to the monetary incentives laid out by governments looking to lead the way in the fight against urban pollution and climate change.

However, EVs are a relatively new technology and the upfront cost of an electric bus is still significantly higher than that of an ICE bus. Fleet managers are then faced with the challenge of computing the life cycle costs of purchasing an electric bus and laying out the case for making the initial investment.

Electric buses

Electric buses have fewer moving parts and wear components, and their parts typically have longer life cycles, which significantly reduces the need for recurring maintenance. On the other hand, components are generally more expensive, which means there are significant gains in increasing their life as much as possible. Batteries are by far the most expensive component of electric buses, accounting for an average of 40% of the cost of the vehicle.

For this reason, public transport fleet operators looking to make a profitable transition to electric buses must make certain considerations about how they are planning to extend the life cycle of their vehicles’ batteries.

1. Do I have visibility over internal faults?

In the old days, vehicle maintenance would be performed at estimated intervals, with breakdowns occurring unexpectedly and causing service disruptions. Now, with the appropriate technology in place, maintenance work can be scheduled according to real-time alerts that indicate that a component is going to break… before it does.

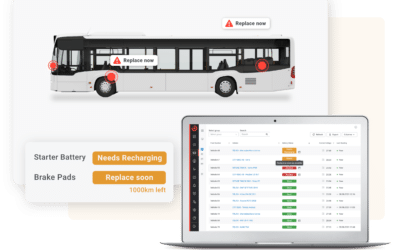

Stratio’s predictive maintenance platform uses AI to provide real-time, actionable insight into the internal faults of electric buses, allowing maintenance managers to diagnose malfunctions remotely without having to recall a vehicle off the road and physically look into it. This is a strategic advantage that effectively lowers the cost of operating an electric bus since it prevents costly downtime and expensive, unplanned trips to the workshop.

2. How is the vehicles’ range going to change over time?

Much like our smartphones’ battery life decreases over the years, the range of electric buses becomes shorter over time. An electric vehicle that has an estimated range of 300km when new and only needs one charge to complete its daily routes, may require two charging sessions to complete the same distance. Some variation in the range is expected due to uncontrolled factors, such as weather, route and vehicle load.

However, current batteries lose capacity irreversibly and provide less and less energy over the years. Range limitations cause logistical problems to public transport fleet operators, who need to plan routes taking into account the maximum range the vehicle can do and the availability of chargers along the route.

For this reason, Stratio has worked with the University of Halmstad and Caetano Bus to build a regression model that consumes the battery data we collect on-board the vehicle and other variables affecting vehicle range, and can accurately predict what is the expected battery capacity loss in the next few years. The findings of the project, named Battery Cortex, went on to be implemented in the Stratio predictive maintenance solution.

The platform leverages advanced data analytics and machine learning models to provide public transport companies with the peace of mind of knowing with precision how their buses’ batteries are going to perform in one, two, or five years time. It also shows fleet managers an accurate prediction of the current range of the vehicle, calculated on the battery capacity and adjusted to account for the estimated capacity loss, as well as alerts for unexpected battery faults.

3. How can I plan operations to optimize battery life?

Mindful of the range losses in electric buses, public transport fleet operators may make certain operational choices aimed at extending the battery life cycle and maintaining its capacity over time. Manufacturers offer guidelines on how to do that, but their main concern is to prevent excessive degradation during the warranty period.

The Stratio platform performs real-time monitoring of “Usage Optimality” metrics targeted at extending battery life beyond warranty. These include monitoring of the State of Charge (SoC) over time and Depth of Discharge (DoD), i.e. how much the battery is discharged between consecutive charges.

Visibility over those two parameters is essential to extend the life cycle of EV batteries, which maintain their capacity for longer if the SoC is kept between 20% and 80% and the DoD is lower than 60%. The fleet operator can visualize the SoC and DoD scores and understand if the operation profile can be changed to maximize battery life, reducing the total cost of ownership of electric buses. This type of analysis is fundamental for an operationally successful and profitable EV fleet deployment.