Reduced operations and maintenance costs, better air quality in our cities, less vibrations, less noise, and zero exhaust emissions: transitioning to Electric Buses should be a no-brainer for public transport service providers.

However, the generous incentives laid out by local and central governments to encourage adoption are bound to decrease, leaving fleet operators with the challenge of remaining profitable and competitive while dealing with an immature technology such as EVs.

EV Battery packs, in particular, can cause significant pains to public transport fleet managers. Batteries are the very core of EVs, and their performance and their lifespan are key factors influencing the total cost of ownership of electric buses and can make the difference between a successful investment and an unsuccessful one.

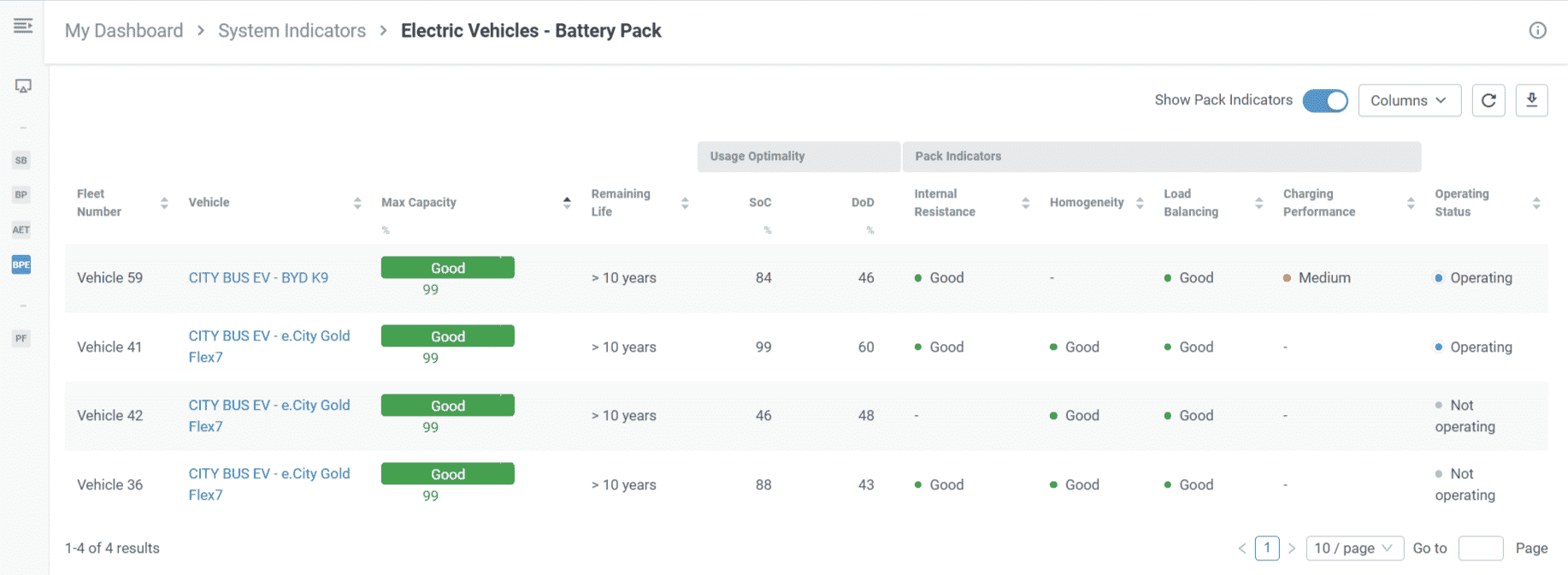

EV Battery Pack feature from the Stratio Platform

To tackle these challenges, Stratio partnered up with Caetano Bus and the great minds at the University of Halmstad to set up the Battery Cortex project, aimed at providing EV OEMs and fleet operators with insights into the quality, faults and anomalies of the battery packs, the most critical component in EVs.

The project, which ran from November 2020 to October 2021, resulted in the development of machine learning and AI models that enable faster R&D iterations (vehicle improvements) and a continuous enhancement of the offer available to end-users, providing better insights to EV assets.

About the machine learning and AI models

The machine learning and AI models developed by the Battery Cortex are fed data collected from battery signals and parameters. These include the batteries’ specifications, pack voltage and current, cell voltage and current, temperature, state of charge, charge/discharge power, and more. The algorithms use this data to output an assessment of the condition and performance of the battery pack.

What is different between existing AI models and those developed by the researchers of the Battery Cortex Project is that, rather than just collecting and analyzing battery data, the framework they designed takes into account vehicle data as well.

This is important because the variables that influence the lifespan of an Electric Bus’ battery pack include things like air conditioning and external temperature, therefore the more granular the data collection is, the better and the more accurate the prediction will be.

Predictive battery analytics

More accurate Predictive Battery Analytics enable public transport service providers to plan accordingly – whether it is maintenance schedules, or which buses to put on the road on a specific day. It also means that public transport fleet managers can justify the initial investment of purchasing an electric bus in light of the extended lifecycle of batteries granted by optimized and monitored charging patterns.

In case of warranty claims, a traceable history of how the battery was charged and used can also come handy to fleet maintenance managers looking to prove that best practices were followed.

Why can’t PTOs rely on Battery Management Systems (BMS)?

When creating batteries, manufacturers rely on standard assumptions on the environment in which a vehicle will be used. However, by virtue of being assumptions, these standard use cases are not representative of the corner cases and the unexpected usage conditions that might occur in real life.

This means that public transport operators (PTOs) might find themselves with vehicles that, despite having the same type of batteries mounted, have a widely different range and lifetime.

Despite the BMS within the battery being able to stream sensor data and diagnostic trouble codes, there is still a gap between what this kind of data can tell fleet managers and what actually happens in a real-life setting. For this reason, it is essential to consider the battery in the wider context of the other vehicle components, and how these interact and affect each other within the larger system (a vehicle).

The Battery Cortex Project has therefore focussed on going beyond the data collected by BMS by combining broader vehicle data with battery data to create a better understanding of the expected battery lifetime. This data, inputted in the advanced AI and ML models, is then turned into actionable insights that inform fleet managers of any potential upcoming problem and allows them to anticipate and prevent breakdowns.

One step further: a truly agnostic technology

The Battery Cortex Project and its findings were instrumental for Stratio to be able to offer a mature and reliable predictive fleet maintenance service for electric vehicles. The AI and ML algorithms developed by the researchers were incorporated into the Stratio Platform, which can now serve electric and ICE fleets alike.

The technology and the mechanics behind these two types of vehicles are widely different, but the predictive maintenance analysis of both can now be integrated and automated into a single platform that gives maintenance managers a single-pane view of the conditions of their fleets.

Not only that: the platform’s data can also be integrated with any other systems used by fleet managers to run operations and maintenance, thus offering the chance to fully automate otherwise time and resource-intensive processes.

- What are the Challenges of Transitioning to Electric Buses? - September 15, 2022

- Stratio Concludes a Research Project on AI Models for Predictive Maintenance with the Support of ELISE - August 30, 2022

- What Are the Benefits of Electric Buses? - August 12, 2022