A bus maintenance software is a critical piece for public transport operators looking to thrive in a rapidly evolving landscape. To overcome the industry’s most pressing challenges, such as staying on top of government regulations, while offering a service of excellence to passengers, operators must embrace the digital transformation.

In the case of bus maintenance software, the industry has made significant leaps forward in terms of what it’s now possible to achieve in terms of management and efficiency. New solutions are available to simplify how operators monitor the condition of the fleet, schedule servicing, and keep vehicles on the road for longer.

Whether operators are responsible for a small bus fleet or a large-scale transport operation, the right solution can streamline maintenance processes, enhance safety, save both time and money, and improve compliance with service-level agreements (SLAs) and transport authorities.

To become more aware of the capabilities of bus maintenance software, we’ll cover 6 of its benefits and explain the advantages of integrating it with predictive maintenance.

1. Cost savings and cost avoidance

One of the most significant benefits of bus maintenance software is the potential for cost savings and cost avoidance. By systematically scheduling and tracking maintenance tasks, transport operators’ maintenance teams can reduce unexpected breakdowns, prevent costly repairs, and avoid error-prone manual activities.

This software is also capable of addressing issues proactively, thus avoiding a reactive approach and extending the lifespan of buses’ components, as repairs stop taking place when parts are already broken down.

Generally, the sooner failures are addressed, the better, as it’s easier and less expensive to fix or repair a problem in its early stages.

If this proactive approach is achieved, there’ll be a reduction in bus breakdowns and service disruptions, enabling operators to save costs. Buses stopped at the workshop and unavailable to operate present a burden to service providers as they aren’t on the road serving passengers and generating revenue.

Moreover, well-maintained vehicles have longer lifespans, so operators can keep buses in service for a more extended period, delaying the need for costly replacements.

To fully maximise cost savings, we recommend integrating bus maintenance software with a predictive maintenance solution. Predictive maintenance is powered by artificial intelligence (AI) algorithms and helps identify vehicle failures with high precision and well in advance. This innovative form of maintenance presents a broad set of cost savings, including:

- Prevention of expensive breakdowns

- Replacements of parts at optimal time

- Reduction of engineering costs

- Extension of buses’ lifespan

- Increase of the mean time between failures (MTBF)

2. Compliance benefits

Compliance with safety regulations and standards is a non-negotiable aspect for a public transport operator. To comply with regulations and SLA terms set and monitored by transport authorities and agencies, operators must provide efficient, safe, and reliable transport services.

Bus maintenance software enables compliance through the real-time monitoring of vehicles’ conditions. It allows technicians to forecast maintenance needs, minimise downtime, and optimise maintenance productivity.

The forecast of maintenance needs is achieved with condition monitoring. This gives operators the necessary visibility over the state-of-health of critical components in real-time, such as the brakes, engine and electrical system, providing the necessary information for effective decision-making about maintenance schedules.

Downtime minimisation, for instance, is about identifying and addressing issues before they lead to breakdowns and safety concerns, reducing the duration of unplanned downtime and contributing to service frequency and punctuality.

Lastly, the optimisation of maintenance productivity is powered by real-time visibility over vehicle components, giving maintenance teams the ability to plan activities more efficiently and order parts in bulk, leading to better pricing and freeing up technicians’ time to focus on higher-priority tasks.

Connecting this software with a predictive maintenance system can set the bar of compliance even higher, as it fosters an improvement of passengers’ experience by enabling transportation services to run smoothly with fewer disruptions and delays, resulting from a well-maintained fleet performing optimally to meet customers’ expectations.

The reduction of lost km due to mechanical failures, in particular, can help operators stay below the threshold set by their SLAs and avoid regulatory fines. Furthermore, by creating an integrated, data-centric ecosystem, operators can leverage the capabilities of maintenance, operations, and workshop management solutions to optimise routes, schedules, and resources, leading to more efficient and cost-effective operations.

3. Optimised maintenance productivity

Efficiency in maintenance operations is crucial to ensure the smooth functioning of a bus fleet. It fosters a better allocation of resources and improves the work order and inventory management.

By relying on software to plan maintenance operations, teams can prioritise tasks based on urgency and importance, ensuring that the right vehicles get repaired and fixed, thus improving productivity.

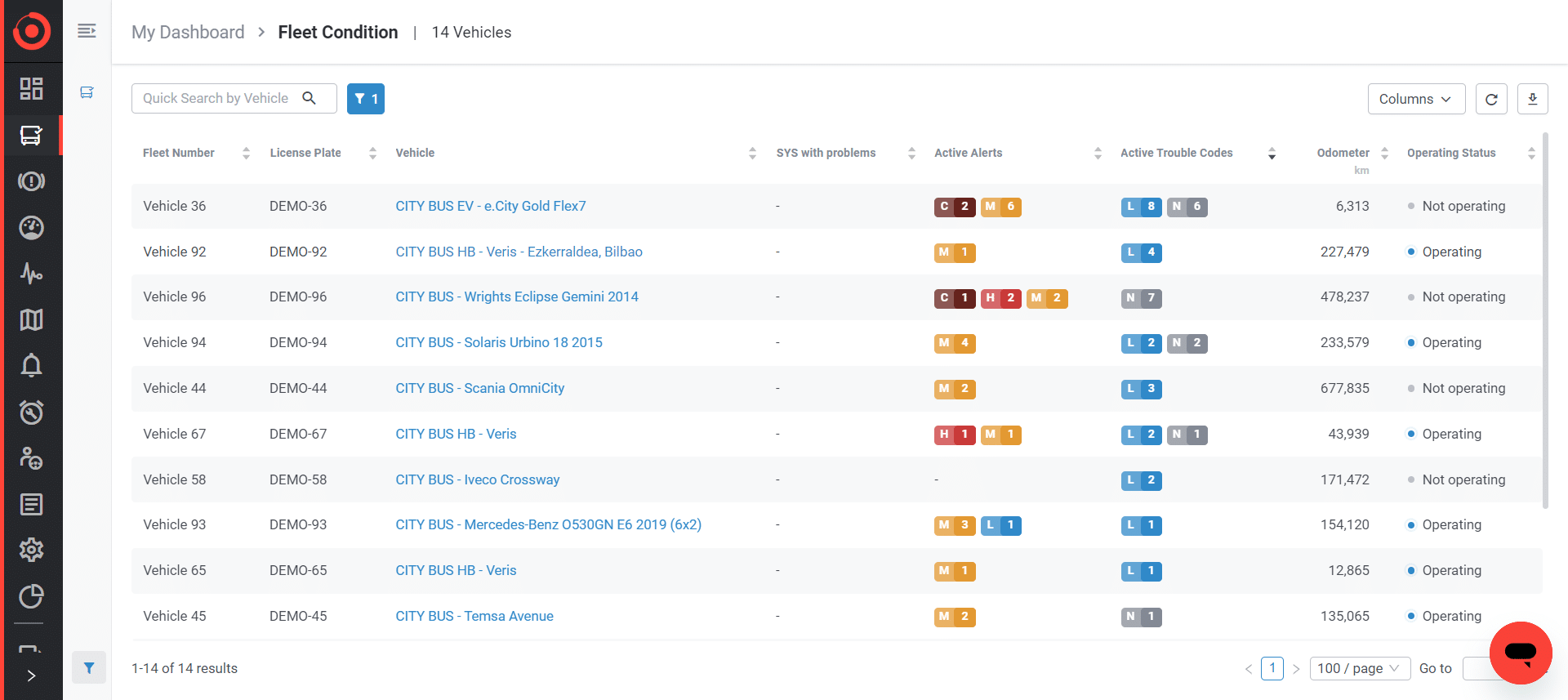

Stratio’s predictive maintenance solution gives the upper hand to maintenance teams by showing them the real-time condition of their fleet, enabling vehicles with active critical alerts (e.g. brake pressure too low) to be quickly addressed.

This also improves workflows, as teams can focus their attention on the most critical tasks, instead of wasting time and resources on vehicles that don’t require urgent interventions.

Ultimately, inventory management is also beneficially impacted because maintenance teams can order parts in bulk and in advance, ensuring that they’re available when it’s most needed, thus avoiding costly downtime.

4. Streamlined maintenance scheduling

Effective scheduling is the backbone of successful bus maintenance.

A reliable software will allow you to create and manage maintenance schedules for each vehicle in your fleet, ensuring that buses receive timely inspections and repairs, reducing the risk of unexpected breakdowns and improving overall fleet reliability.

With a suitable solution, you can configure maintenance and inspections for specific timelines (e.g. get neral maintenance for every 40.000 km), and visualise automatic data that calculates the remaining distance and time for the next expected vehicle’ service.

The automation capabilities of these systems also safeguard maintenance technicians from error-prone and time-consuming tasks like odometer readings and fluid level checks, as these activities can be automatically collected. By streamlining these processes, technicians can leverage their time to focus on more critical tasks and rely on optimised maintenance plans powered by real-time and up-to-date data.

Another advantage is the minimisation of downtime, as well-planned maintenance schedules avoid the risk of buses being unexpectedly out of service due to maintenance needs.

5. Real-time data and analytics

In the digital age, real-time data is invaluable. Bus maintenance software provides transport operators not only with the ability to leverage their data to gain real-time insights into the condition of their fleets but also with the chance to use data to predict faults before they happen.

With access to data and analytics, operators can make informed decisions about maintenance, repairs and replacements, and manage their fleet more efficiently.

With predictive maintenance, real-time data is used to power advanced artificial intelligence (AI) models that detect and alert teams of vehicle faults, enabling the prevention of vehicle towing and overspending on emergency repairs.

For example, with predictive maintenance, teams can anticipate issues with vehicles’ air compressors. Air leaks, which are notoriously common but difficult to spot and locate, are spotted early and measured by size. This means that maintenance teams can prioritise which vehicles will need servicing and gain visibility over previous blind spots.

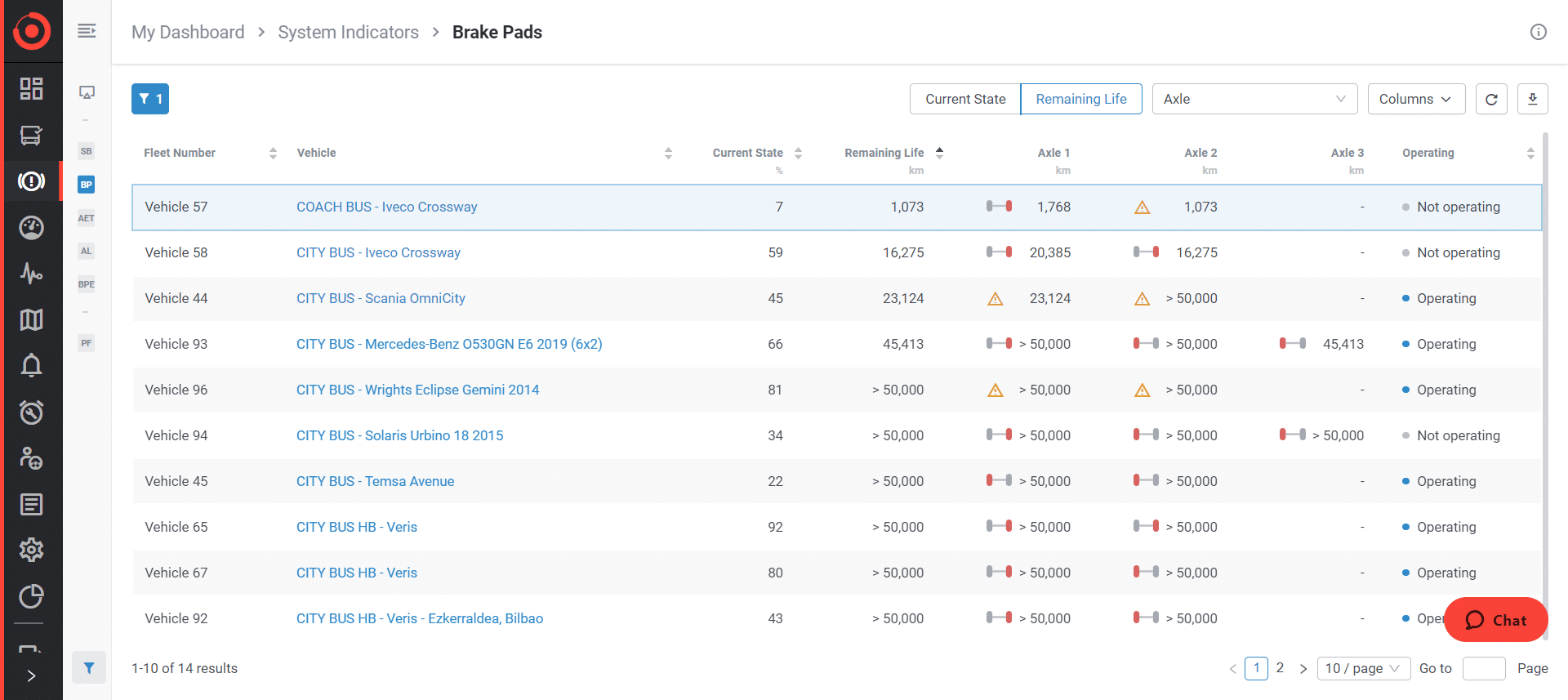

Another practical example is brake pads. This component is paramount for the safety of operations, and with predictive maintenance, teams can receive wear and tear estimations in real-time over their condition, enabling replacements at the right time (when the component has reached the end of life), consequently avoiding overspending and improving productivity.

Lastly, it promotes data-driven decision-making, as fleet operators can leverage data and analytics to make informed decisions regarding maintenance and operations.

6. Improved fleet reliability

By implementing a bus maintenance software, transport operators can significantly enhance the reliability of their bus fleet. With reliable bus services, operators can reduce the likelihood of disruptions, consequently improving customer satisfaction and ensuring a better brand reputation.

A software of this kind provides real-time data, enabling operators to improve their decision-making and upgrade to proactive maintenance. The impact on the servicing is immense, as unexpected vehicle breakdowns are prevented and buses can be intervened in off-peak periods, without compromising the fleet availability when it matters the most.

To take reliability to a further stage and achieve operational excellence, predictive maintenance is recommended for operators. Here are some of the ways it enables it:

- Minimisation of lost mileage

- Better compliance with service-level agreements

- Improvement of performance metrics

- Extension of the mean time between failures (MDBF)

- Real-time vehicle monitoring to ensure safe and good working conditions

All in all, safe and reliable buses are less likely to experience accidents or disruptions and are vital to ensuring the satisfaction of those who depend the most on public transport services – the passengers.

Why is the integration with predictive maintenance so important?

Opting for a bus maintenance software is already a firm step to leave behind reactive maintenance and manual and time-consuming processes. However, to drive operational excellence, increase cost savings, and offer safe and reliable services that passengers can rely on, a predictive maintenance system is needed.

Stratio’s predictive maintenance solution uses the power of data and AI to provide predictive insights that enable operators to anticipate breakdowns and minimise unplanned downtime. This results in maximised vehicle availability, as component failures can be averted before they cause service disruptions, unexpected costs, and damage passengers’ trust.

Moreover, these predictive insights can be leveraged to streamline service teams’ workload and guarantee optimal efficiency. They also ensure that critical components are in good working order, which directly impacts the safety of employees, customers and the general public.

Explore the real-life impact of predictive maintenance by accessing our case study with Arriva Czech Republic. It shares the results achieved by our client after deploying our solution across 543 buses of their fleet.

- 6 Benefits of Implementing a Bus Maintenance Software - April 17, 2024

- Unlocking a more sustainable future with data-powered predictive maintenance - January 15, 2024

- How Can Artificial Intelligence Support Public Transport Operators? - September 20, 2023